My Business Grows 300 Percent Every Fall. Here’s What that Has Taught Me.

- John Kramer

- Cambridge Air Solutions

[A note from Tugboat Institute: Please note the postscript at the end of this article, in which the author comments on the connection of this topic to the impact of the COVID-19 pandemic.]

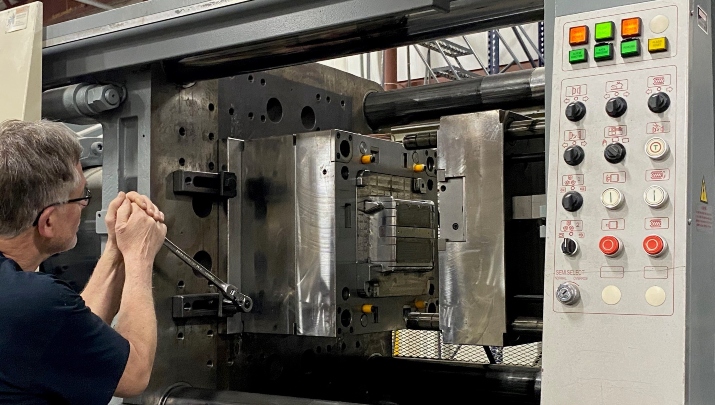

As a manufacturer of industrial heating and cooling technology, our business, Cambridge Air Solutions, surges 300-400 percent each fall. Everyone generally wants to have those systems installed in new construction before winter, and if you’re replacing your system, you typically do so in the last few months of the year. To meet that cyclical demand, we hire a large number of seasonal employees.

Hiring, training, and integrating a seasonal workforce can present challenges, but we have developed an approach that is guided by our Purpose, which is to enrich every life we touch. We don’t want to simply hire temporary workers without considering the long-term. We want to enrich their lives and behave toward them as we do toward all of our employees, customers, and suppliers: with unconditional love and high expectations.

This approach toward our seasonal employees led to the creation of Cambridge Unleashed, a 4-6-month seasonal work program developed by our Vice President of Human Resources, Meg Brown. The goal was to provide opportunities for seasonal employees to develop hands-on lean manufacturing skills and experience that will help them either progress into a full-time position at Cambridge Air Solutions or, if we don’t have a position for them, launch a career at another firm.

A central pillar of the Cambridge Unleashed program is a video series that we developed to showcase our seasonal employees’ experiences and expertise as they grow and develop in their role—and specifically their innovations related to the principles of lean manufacturing.

Every seasonal (and long-term) employee is required to read Paul Aker’s book 2 Second Lean: How to Grow People and Build a Fun Lean Culture. This book lays the foundational understanding of lean and describes the simple, “fix what bugs you” approach to waste reduction. Alongside the skills training they undergo, this education in lean allows seasonal employees (who we refer to as “unleashers”) to step into the rhythm of our operation and their specific roles ready for success—and primed to offer insight into continuous improvement.

Our daily schedule includes a 15-minute morning meeting, which all unleashers attend, which includes a review of revenue and other milestones and highlights process improvements. After the morning meeting, we dedicate 30 minutes to non-production time, during which we don’t want employees producing a product or jumping into their functional roles. Instead, we ask them to focus on how they can make their job easier, better, safer, cleaner, or a help somebody else solve a problem—and make a video sharing their improvement.

Each day, we highlight the improvements and innovations that our employees, including the unleashers, develop during this period in our daily Morning Meeting. Each video shares an employee’s lean innovation, showcasing employees’ creativity and skills.

The videos ultimately provide several important benefits to the employees and to Cambridge Air Solutions. First, if we do not have a position for the seasonal employee after their temporary position ends, their improvement videos are compiled in a playlist they can use to promote their skill sets and innovations to prospective employers. In addition to helping unleashers share their skills and innovations, the daily habits and continuous improvement mindset that these videos reflect, and which are central to our culture, serve to attract unprecedented numbers of candidates when we have open positions. This past year, we were seeking to hire 20 unleashers to fill seasonal roles, and we had 574 applications. And that was with a four percent unemployment rate.

Beyond the video series, the broader Cambridge Unleashed program provides seasonal employees opportunities to fully engage in our culture, take on short-term leadership roles, and connect with long-term employees. The additional focus on training and engagement for these employees has resulted in tremendous improvements to our safety record and production capacity and throughput. And, we’ve seen the morale of the plant grow across the board as unleashers and full-time employees connect and increasingly recognize that we’re all pushing toward the same common goals. Now, we train together, we innovate together, and we celebrate together.

Personally, watching the Cambridge Unleashed program develop and seeing the benefit to the individuals and to our Evergreen company has been extremely rewarding. When we help people tap into their creativity to solve problems at work, it not only benefits our process and productivity, it enriches and enhances lives beyond our plant. Whether they are working with us for six months or for many years, we want our people to go home at the end of the day knowing they have created valuable solutions because when they do, they bring the confidence and fulfillment of that experience into their relationships with their families and their engagement in their communities.

John Kramer is the CEO of Cambridge Air Solutions.

Postscript 09.11.2020

In the wake of the COVID-19 pandemic, our company shifted all of our daily rhythms to a virtual format, which was an early practical step to ensure safety. In a broader sense, we have seen a significant impact to our ability to attract applicants, resulting in a lower volume in our Unleashed recruiting pipelines than prior years. However, we are able to close the candidates who do apply and get them onto the team, which I believe points to our ability to demonstrate safe work practices even during COVID. In addition, the “Protect This House” rallying cry, which we embraced in the early days of the pandemic, has been a key step toward preparing for the busy season. Our team members are motivated to bring in Q1 of FY21 and willing to do what it takes to keep themselves safe while also continuing to make product for our customers.

More Articles and Videos

Fireside Chat with Dave Thrasher, Dan Thrasher, and Dave Whorton

- Dave Thrasher, Dan Thrasher, & Dave Whorton

- Supportworks and Thrasher Group

Get Evergreen insight and wisdom delivered to your inbox every week

By signing up, you understand and agree that we will store, process and manage your personal information according to our Privacy Policy